Dental Aluminum Oxide Micro Blaster With Water Spray

- M&Y

- CHINA

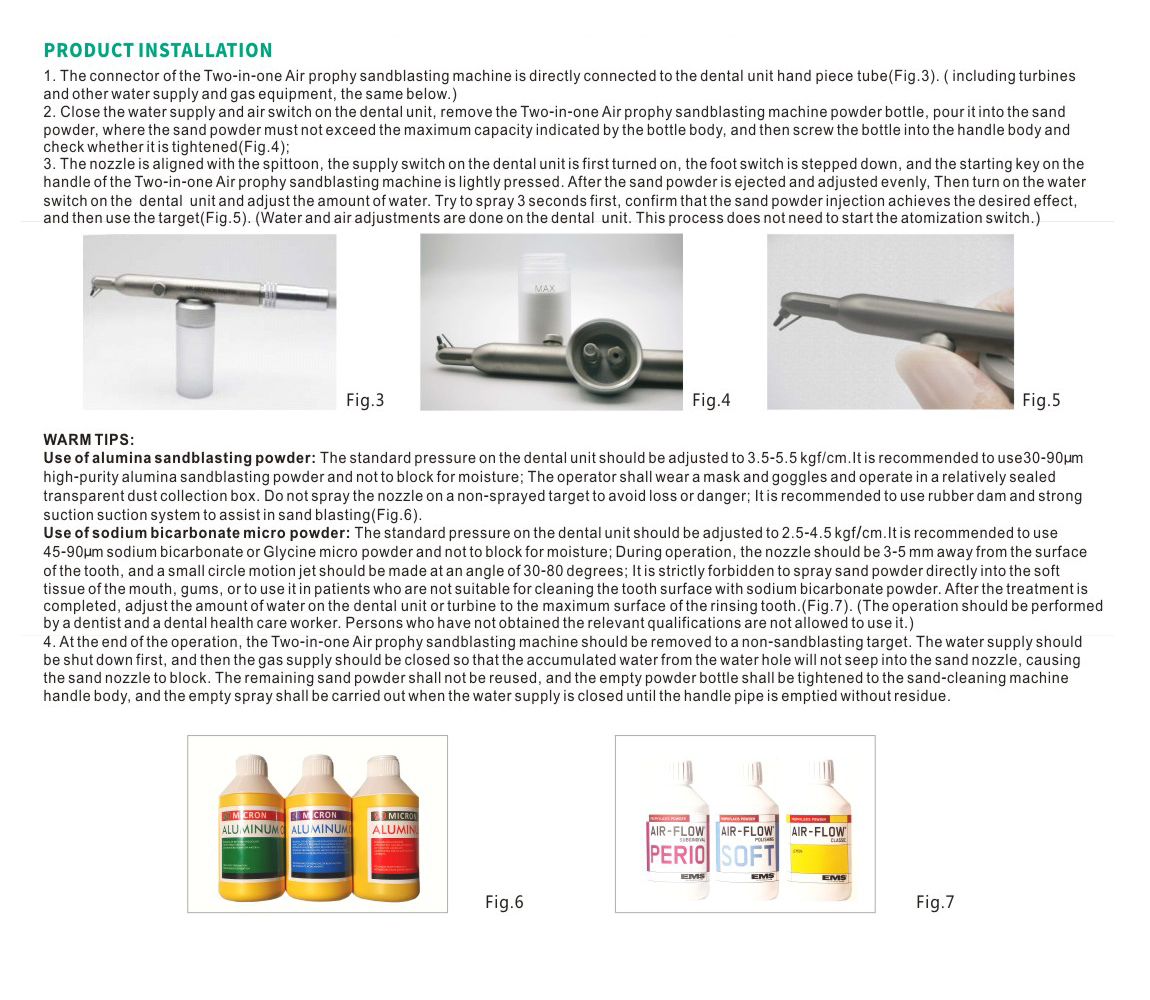

- 5Days after payment

- 5000unit/month

Dental Aluminum Oxide Micro Blaster With Water Spray

tungsten nozzle ,two In one fuction

used for cleaning and coarsening of the surface before bonding.

surface microcoarsening in the treatment of porcelain or resin restorations.

Dental Water Cooling Air Abrasion Unit Mini SandBlaster

Two-in-one sandblasting system Various types of alumina powder Sodium bicarbonate powder available.

M&Y Dental Aluminum Oxide Micro Blaster With Water Spray is designed with ergonomic 360-degree rotating nozzle for more flexible and convenient operation.

The hand-controlled buttons ensure a safer operation.

It comes with an anti-backflow function to prevent sand powder from flowing back into the dental chair's water vapor system.

The gun can be disinfected at a high temperature of 135 degrees to prevent cross-infection.

The Dental Aluminum Oxide Micro Blaster With Water Spray is made of high-quality stainless steel and special wear-resistant metal materials, making it robust and durable.

The nozzle is made of tungsten steel material to avoid nozzle perforation and effectively prolong the product's service life.

The built-in water spray cooling system eliminates powder flying around, preventing air pollution.

The portable connectors can directly connect to the dental chair's air and water supply pipes, saving time and effort.

It is compatible with various types of alumina powder and sodium bicarbonate powder.

Product parameters

-Product name:Dental Aluminum Oxide Micro Blaster With Water Spray

-Material:stainless steel body/Tungsten nozzle

-Connector:2Hole/4hole /NSK PTL coupling/ kavo coupling

-Air pressure:0.25-0.35Mpa

-Water pressure:0.2-3.5Mpa

-Water spary: water spary cooling

-Autoclave:All parts autoclavable

-.Brand :M&Y/OEM

-.OEM ODM acceptable

-.M&Y dental factory directly supply

-. Search distributor from global.

- Extraoral application: used for cleaning and coarsening of the surface before bonding.

-Intraoral applications: surface microcoarsening in the treatment of porcelain or resin restorations.

-Warraanty:12Months

Product application

Surface cleaning and micro-roughening before bonding:

Alumina powder is used to clean and slightly roughen the surface before bonding procedures. It is commonly used for all-ceramic and metal restorations to improve bonding strength.

Tooth surface grinding:

In some dental restoration processes, dentists may need to perform minor grinding on the tooth surface to provide better bonding surfaces for dental crowns, bridges, or other restorative materials. The dental alumina sandblasting gun allows precise control over the sandblasting force and direction, facilitating accurate grinding.

Dental material cleaning and pre-treatment:

Before dental restorations or other treatments, dentists may need to clean and pre-treat the tooth surface. The dental alumina sandblasting gun is used to remove debris and old restorative materials from the tooth surface, preparing it for subsequent treatments.

Dental Aluminum Oxide Micro Blaster With Water Spray Using sodium bicarbonate powder can eliminate tobacco stains, food residues, and dental plaque in the interdental spaces, preventing dental calculus formation and gingivitis. It also enhances the natural shine and whiteness of teeth, improving their appearance.

Dental polishing:

The Dental Aluminum Oxide Micro Blaster With Water Spray can also be used for dental polishing, creating a smoother and more aesthetically pleasing surface for dental restorations, enhancing oral comfort. Polishing helps reduce surface roughness, making it more difficult for bacteria and stains to adhere to teeth.

Safety tips

1. In the course of use, the operator must wear a mask and a goggle, and the patient must wear a goggle.

2. Pressure air straight to the gums and exposed dental pulp sandblasting will lead to bubble embolism, so when applied to the mouth, it is recommended to use a rubber dam and a strong suction system.

3. If the TWO-IN-ONE Sandblasting system accidentally dropped again, should be checked bottle and nozzle before use, if damaged, should be replaced immediately, when stop use must disconnect air;

4. The TWO-IN-ONE Sandblasting system recommended Use 50-90um high purity alumina sand powder, and no caking damp;

5. Alumina powder injection powder should not be higher than the maximum range defined by the bottle. When the capacity is lower than the 1/3 bottle, the air supply should be closed immediately and the sand powder should be filled in time.

6. Sodium bicarbonate powder all size available, When the capacity is lower than the 1/3 bottle, the air supply should be closed immediately and the sand powder should be filled in time.

In the case of blockage:

1. blocked nozzles in a few seconds

The nozzle can be dredging clean.

2. Move the sand bottle, USE 15 # wire respectively dredging nozzle and sand hole and the air inlet, then screw on the sand bottle, the air pressure to the maximum (6.0kgf/cm -), using compressed air to dredge;

3. If all of the above methods can not be solved, please contact the local distributors or send them back to the factory immediately.