Dental 20 Degree Surgical Surgery Straight Handpiece

- M&Y

- CHINA

- 5 Days after payment

- 5000unit/month

Dental 20 Degree Surgical Surgery Straight Handpiece

1.Transmission gear is made of high strength alloy steel

2.Adopted Imported Bearing Smooth rotation,low noise, long life.

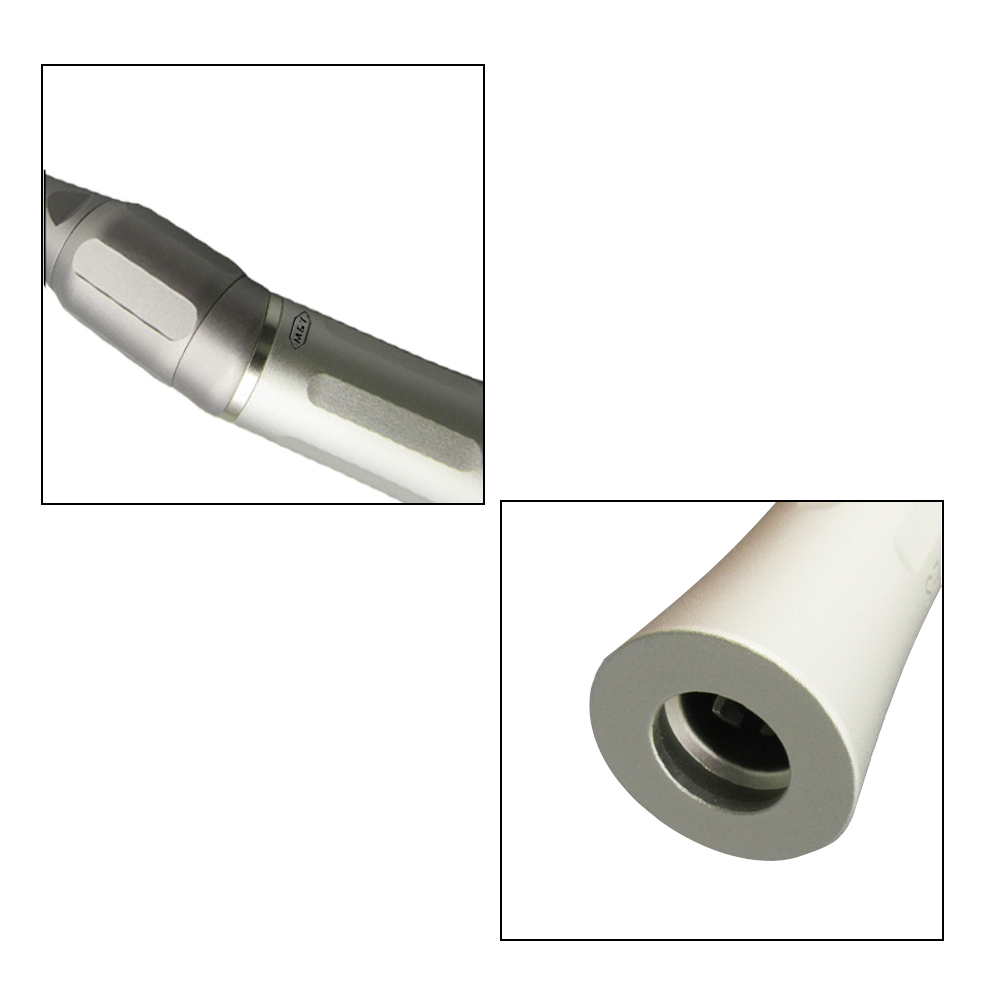

3.The international standard interface, universal.

Dental 20 Degree Surgical Surgery Straight Handpiece

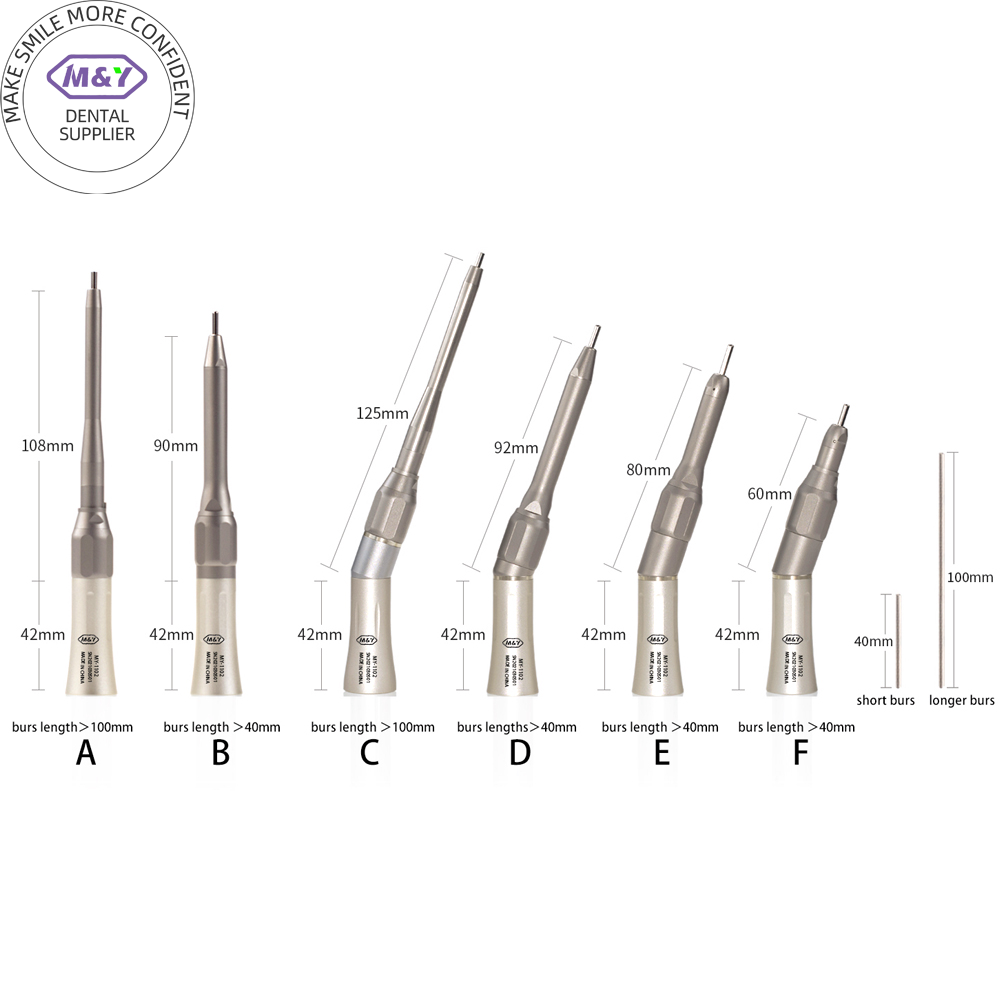

| Bur Applicable | Gear ratio |

| 2.334-2.355mm | Single water spray |

| Air pressure | Degree |

| 0.30Mpa-0.35Mpa | 20 Degree |

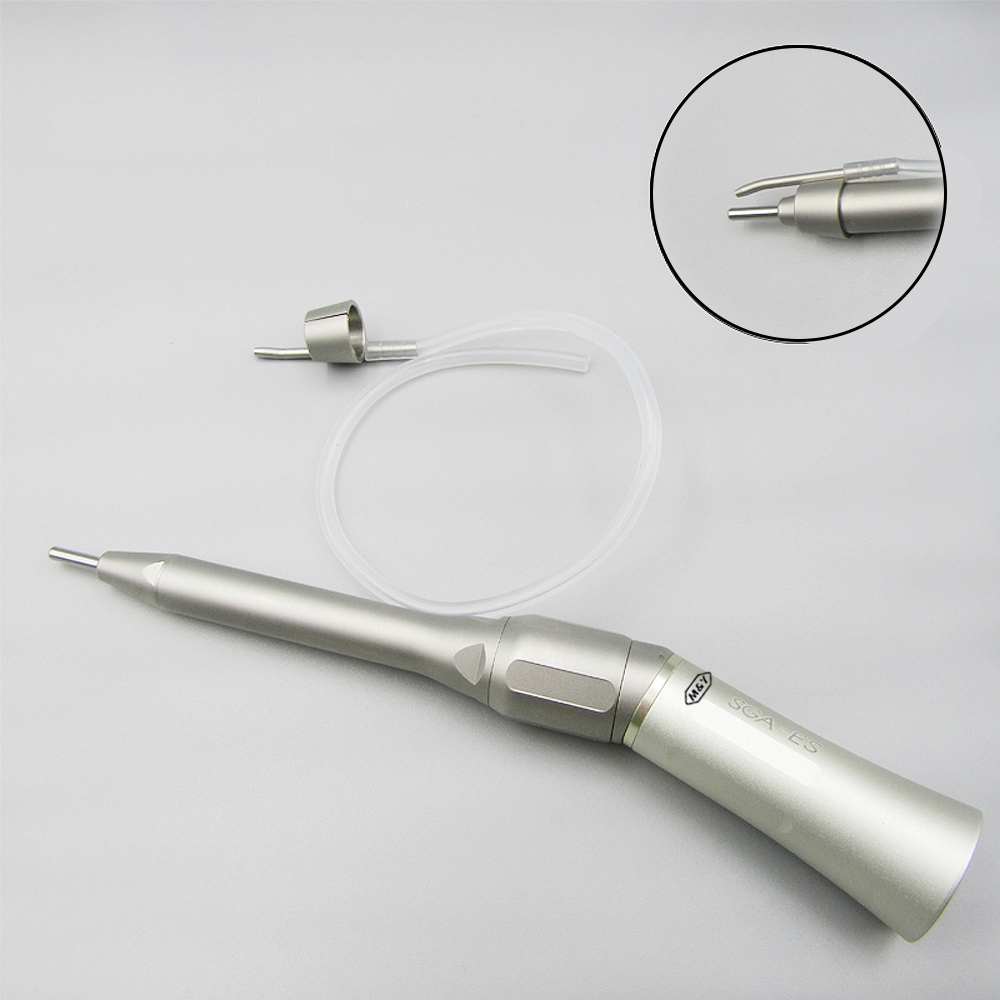

dental surgery handpiece

Features:

The surgical handpiece is suitable for implantation, orthopedics, ear, nose and throat, maxillary sinus lifting, bone extraction, bone grinding and other surgical operations.

When surgical handpiece is in use, it rotates, emits water, and exhausts air at the same time. The air and water are in the same direction, so what it comes out is usually water mist, which covers a relatively large area. This relatively strong airflow covers a relatively large area. Large air mist can cool the bur and the tooth well during tooth preparation and pulp opening, but if it is during tooth extraction, it will easily cause subcutaneous emphysema in patients, and the airflow is relatively strong, easy to Bring some debris deep into the tissue.

1. Dental handpiece cleaning and maintenance principles

(1) The appropriate cleaning and maintenance method should be selected according to the internal structure or function of the dental handpiece.

(2) Special-purpose dental handpieces should be cleaned and maintained in accordance with the instructions provided by the manufacturer or supplier.

2. Dental handpiece cleaning method

(1) Manual cleaning method

① After the dental handpiece is used, use the water and air system of the dental comprehensive treatment table to flush the internal water and air channels of the dental handpiece for 30 seconds with the needle on.

②Remove the dental handpiece from the quick interface or connection line, remove the bur, and remove surface pollutants. Dental handpieces with optical fibers can be used to blow off particles and dust on the surface of the optical fiber with an air gun, and wipe off stains on the surface of optical fibers; the surface of dental handpieces with threads can be cleaned with a soft brush under running water.

③ Use pressure canned cleaning lubricating oil to clean the air inlet pipeline of the dental handpiece, or use a pressure water gun to flush the inner pipeline of the air inlet hole, and then use a pressure air gun to dry. The mobile phone with detachable parts should be disassembled and cleaned; the non-removable mobile phone for dental implant can be cleaned with a pressure water gun; after cleaning the dental handpiece with a pressure water gun, the internal air circuit should be dried with a pressure air gun as soon as possible to avoid The bearing is damaged; the pressure of the pressure water gun and the pressure air gun should be between 200kPa and 250kPa, and should not exceed the pressure indicated in the instruction manual of the dental handpiece; the dental handpiece should not be soaked in a liquid solution for cleaning.

3. Manual maintenance of dental handpieces

(1) Use the pressure canned lubricating oil to connect the matching oiling adapter or joint to inject lubricating oil into the dental handpiece.

(2) The part of the dental handpiece holding the instrument (chuck or three-valve spring) should be oiled daily.

(3) The internal oil circuit type dental handpiece should use a grease pen to lubricate the chuck or three-lobe spring and bearing.

(4) Refer to the above oiling methods (if applicable) for oiling of low-speed dental bending machines and dental straight machines, and refer to the manufacturer’s or supplier’s instructions for special oiling methods.

Features:

1.Precision design, transmission gear is made of high strength

alloy steel, Perfect Stable and reliable performance

2.Adopted Imported BearingSmooth rotation,low noise, long life.

3.The international standard interface, universal.